Quality management policy of A&P are to provide attractive products and services for our customers.

We have strived to grow into a pioneer top-ranking company in the PCB business based on the three quality management policies: quality first, constant quality innovation and customer satisfaction first policies.

Quality target

Realization of quality first

Continuous quality improvement with creative spirit

Establishment of customer satisfaction priority system

Material incoming

- incoming inspection / periodical reliability inspection / barcode first-in first-out management

- incoming inspection / periodical reliability inspection / barcode first-in first-out management

Internal layer circuit

- lot AOI inspection / width of circuit inspection / impedance inspection (= F / Proof)

- lot AOI inspection / width of circuit inspection / impedance inspection (= F / Proof)

Lamination (multi-layered substrate)

- reliability assurance / adhesive strength assurance (delamination = F / Proof)

- reliability assurance / adhesive strength assurance (delamination = F / Proof)

Drilling

- BIT automated grinding automated lot inspection /

- BIT automated grinding automated lot inspection /

Plating

- medicine concentration, chemicals management/width of plating to be 25㎛ or higher

- medicine concentration, chemicals management/width of plating to be 25㎛ or higher

Outer layer circuit

- lot AOI inspection / width of circuit inspection / impedance inspection

- lot AOI inspection / width of circuit inspection / impedance inspection

PSR (insulation ink)

- automated spray printing / width of printing assurance

- automated spray printing / width of printing assurance

Electrical testing

- four sockets (low resistance) lot inspection (security elements)

- four sockets (low resistance) lot inspection (security elements)

Appearance inspection

- FAOI inspection (only one in South Korea)

- FAOI inspection (only one in South Korea)

Reliability inspection

- according to lots

- according to lots

MES system

Management of product history

- management of product history tracing barcodes through process record registration

- management of product history tracing barcodes through process record registration

Pillar inspection

- establishment of a quality assurance system through computerization of pillar inspection

- establishment of a quality assurance system through computerization of pillar inspection

Information transmission

- transmission of instructions and notices via monitors and DID screens of each process

- transmission of instructions and notices via monitors and DID screens of each process

Production information monitor

- real-time monitoring of production information via DID screens of managers and executives

- real-time monitoring of production information via DID screens of managers and executives

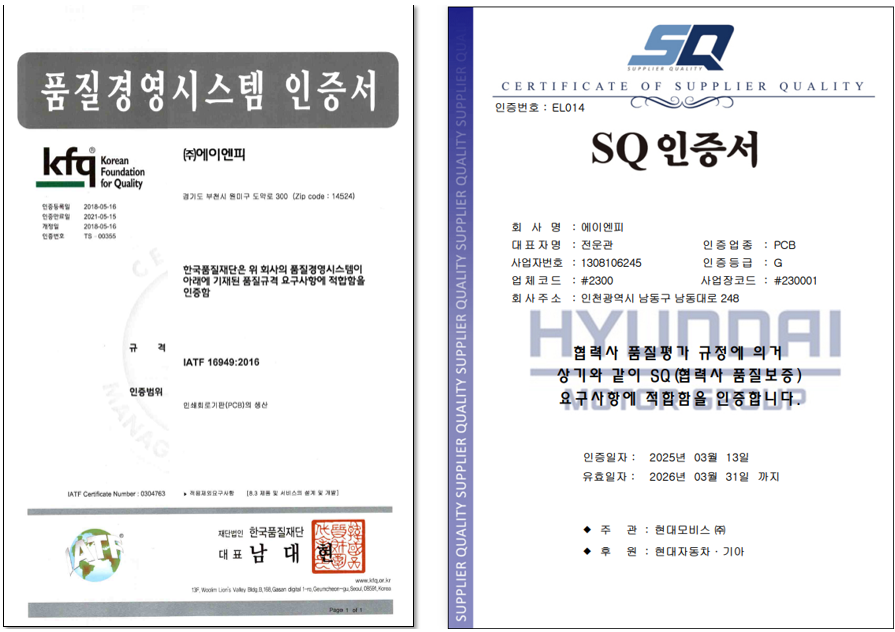

QUALITY ACCREDITATION

품질관리 인증

2018년 IATF16949 인증

2015년 SQ-Mark A등급 (Hyundai-Kia Motors)인증

2005년 ISO14001 인증

2002년 ISO/TS 16949 인증

안전 규격 인증

U.L승인 File No: E82473

Halogen free material U.L 승인

품질검사 규격

IPC-RB-276 Class 3